The standard method of press forming the part requires many steps as opposed to only three steps.

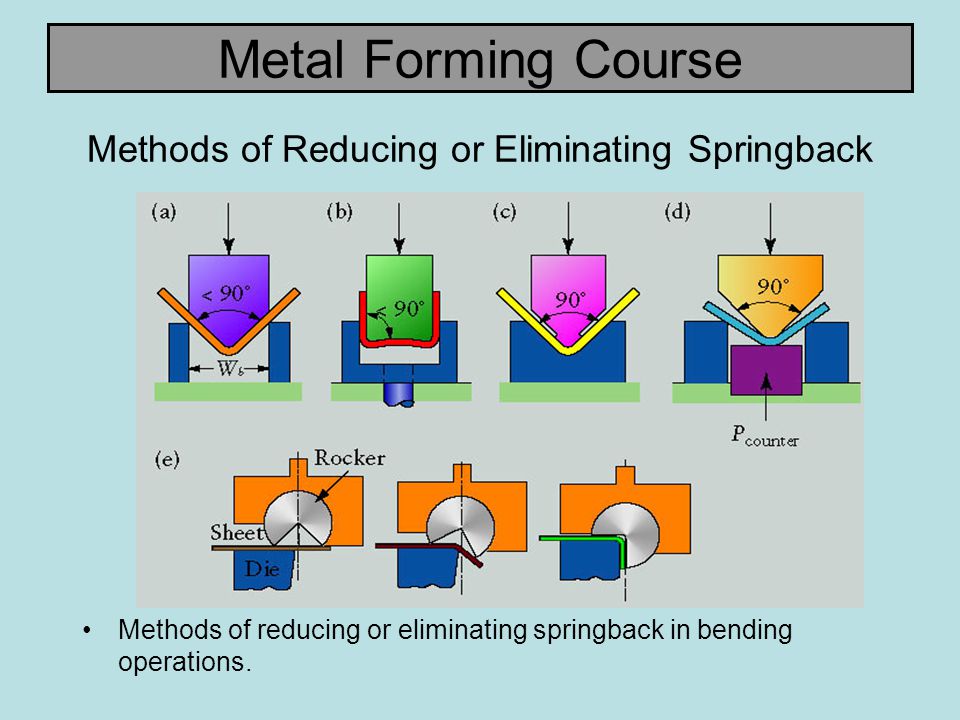

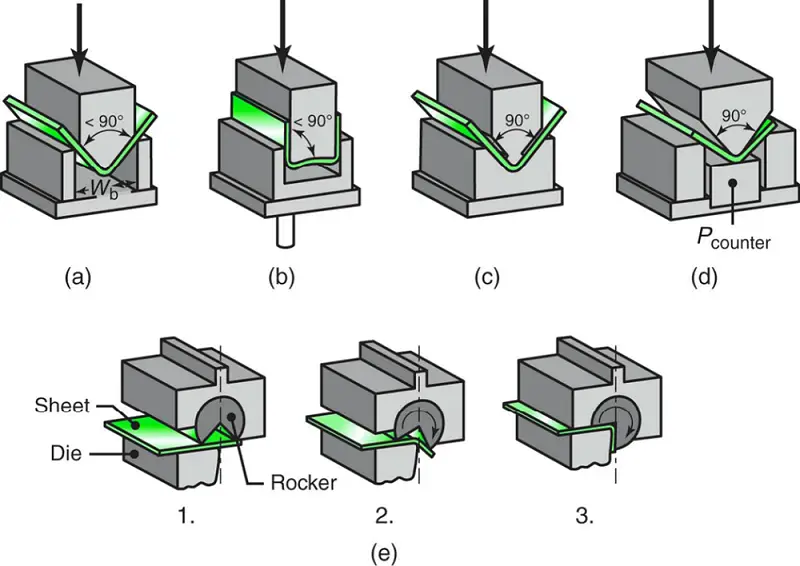

Methods of reducing spring back in sheet metal operations.

Surface condition of sheet.

Sometimes this increment is subdivided into a number of sub increments to avoid numerical instabilities in forming.

A method of pressing sheet material utilizing counterpad pressure to eliminate springback is disclosed.

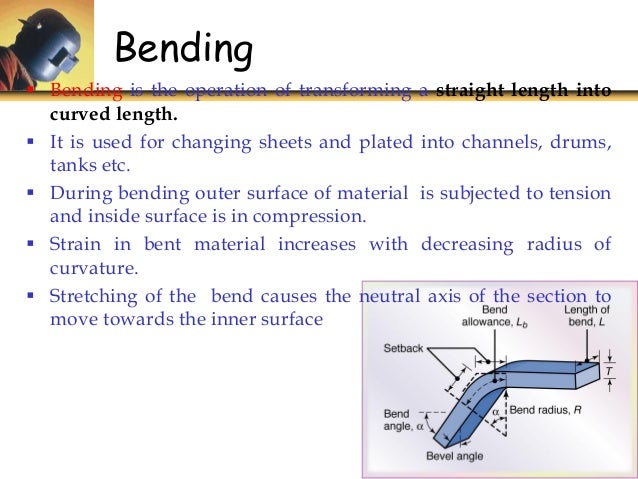

After bending do the hardening process.

Due to the fact the sheet metal work hardens during forming drawing it is desirable to stretch a sheet metal part as much as possible to increase part strength and thereby increase the rigidness of the part and lessen the effect of springback.

Based on this taking the stiffener parts of auto as.

Quality of sheared edges 9.

Anneal before bending to reduce hardness and yield stress which can not only reduce rebound but also reduce bending force.

The spring back has to be compensated to achieve an accurate result.

The springback is mainly an elastic deformation which occurs after sheet metal forming processes.

When a metal forming tool is planned and designed to deform a work piece the shape imparted by the tool will be a combination of elastic and plastic deformation.

During air forming the workpiece springs back slightly when released from pressure as it attempts to return to its original shape.

The sheet material is sequentially bent at pairs of bend radii during first and second increments of striking.

Spring back of deferential die 12 lower than edge bending die.

The amount of springback that occurs is a property of the material and radius.

This paper analyzed the mechanism of deep drawing springback of sheet metal forming and the springback compensation was studied.

Most sheet metal operations stampings sheetmetal products.

After adjustment both inner and outer layers are elongated and the springback trend of the two areas after unloading can be offset to reduce the springback.

Stretch forming is often a more effective solution to springback problems than direct compensation.

In most springback analysis the instantaneous release method is employed according to this method the change of shape of the drawn sheet due to the release of the tools is calculated in one increment.

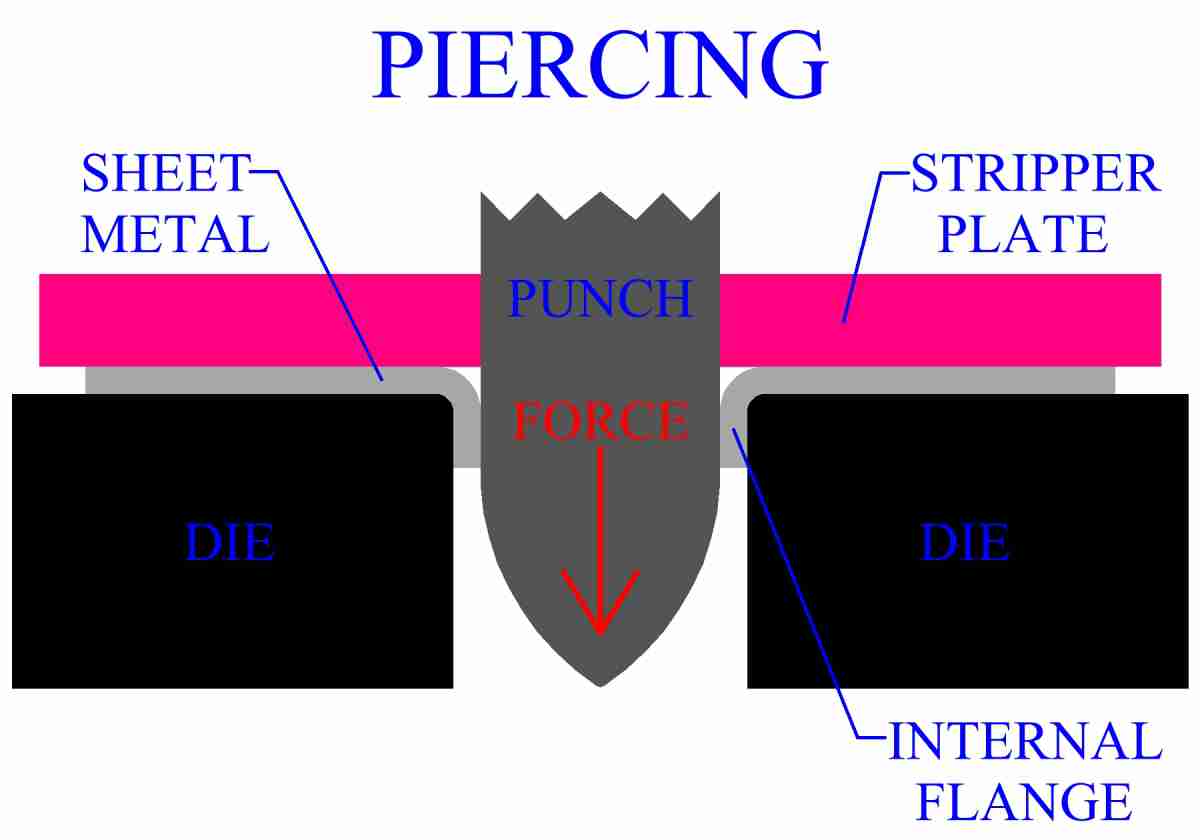

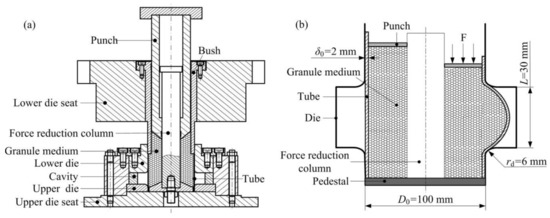

A set of die and punch.

The air forming zone shows that when the press brake exerts pressure on the sheet the metal begins to bend.

Also for decreasing of the tool radius leads reducing spring back.

The effects of material type as shows that using aluminium sheet metal instead of high strength sheet metals spring back is reduced by 56.

Smaller amount of material than other methods.